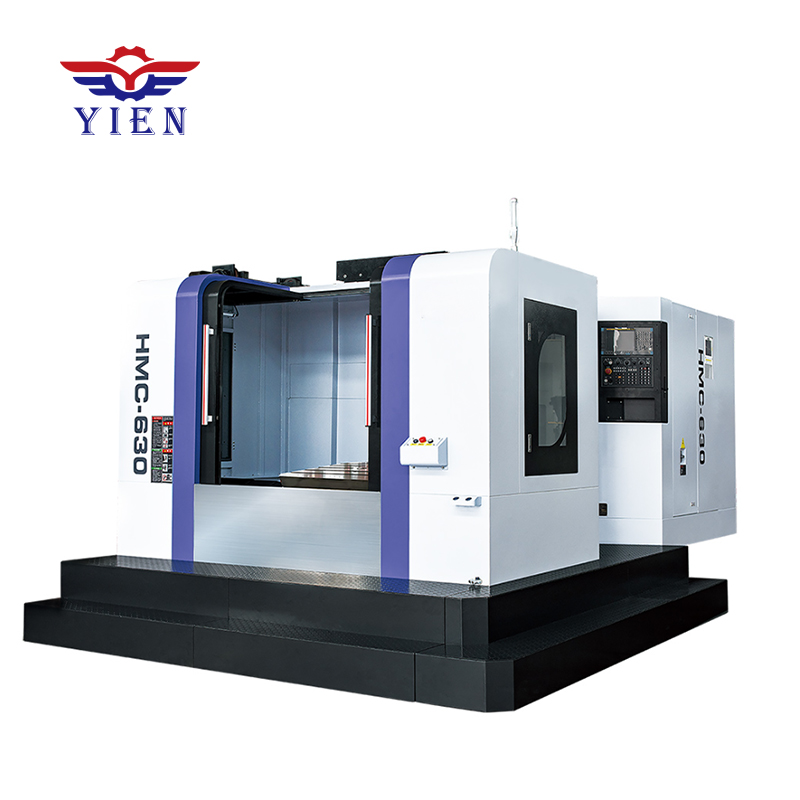

Horizontal Machining Centers: Revolutionizing Manufacturing Processes

The world of manufacturing has witnessed remarkable advancements over the years, and one of the key innovations that has significantly impacted the industry is the Horizontal Machining Center (HMC).

In this article, we will delve into the features, applications, and the future of these powerful machines that have transformed the way we create precision components. 1. Introduction Overview of Horizontal Machining Centers Horizontal Machining Centers, commonly referred to as HMCs, are cutting-edge machines used in the manufacturing sector to produce intricate and precise components. Unlike their vertical counterparts, HMCs feature a horizontally oriented spindle that holds the cutting tool. The workpiece is securely clamped on the machine table, allowing for greater stability during the machining process. Advantages of Horizontal Machining Centers HMCs offer several advantages that make them a preferred choice in various industries. They excel in handling large and heavy workpieces, thanks to their robust construction. Additionally, their horizontal spindle orientation ensures better chip evacuation, leading to improved surface finish and reduced tool wear. 2. History and Evolution The Development of Horizontal Machining Centers The concept of machining centers originated in the mid-20th century, with significant contributions from various engineers and manufacturers. As technology advanced, so did the capabilities of these machines, leading to the development of horizontal machining centers in the late 1960s. Key Milestones in the Evolution Over the years, HMCs have undergone remarkable improvements. The integration of computer numerical control (CNC) in the 1970s revolutionized machining processes, allowing for greater automation and precision. Subsequent advancements in tooling and spindle technology further enhanced the performance of HMCs. 3. How Horizontal Machining Centers Work Basic Principles of Operation Horizontal Machining Centers use a rotating cutting tool that moves along multiple axes to remove material from the workpiece. The horizontal spindle enables efficient machining of various sides of the workpiece without the need for repositioning, resulting in faster production times. Types of Workpieces Created HMCs are incredibly versatile and can produce an array of components, including engine blocks, gears, aerospace parts, and more. Their ability to accommodate different workpiece sizes and materials makes them indispensable in modern manufacturing. 4. Popular Applications Industries Using Horizontal Machining Centers Horizontal Machining Centers find applications in diverse industries such as automotive, aerospace, oil and gas, and medical equipment manufacturing. Their ability to handle complex machining tasks with precision makes them invaluable across different sectors. Specific Use Cases Within these industries, HMCs play a pivotal role in manufacturing critical components like turbine blades, cylinder heads, and hydraulic manifolds. Their accuracy and reliability ensure that these vital parts meet stringent quality standards. 5. Comparison with Vertical Machining Centers Advantages and Disadvantages Horizontal and Vertical Machining Centers each have their strengths and weaknesses. While HMCs excel in production volume and stability, Vertical Machining Centers are better suited for intricate and smaller components. Understanding the differences helps manufacturers choose the right machine for their specific needs. Selecting the Right Option When selecting between HMCs and VMCs, factors such as production requirements, workpiece complexity, and available floor space need to be considered. Consulting with machining experts can assist in making the best decision. 6. Key Features to Consider Precision and Accuracy One of the primary reasons manufacturers opt for HMCs is their ability to consistently deliver high precision and accuracy in machining tasks. This is crucial in industries where the slightest deviation can lead to significant consequences. Spindle Speed and Power The performance of HMCs is influenced by the spindle's speed and power. Higher spindle speeds enable faster cutting, while greater power ensures the machine can handle tougher materials and heavier cuts. Automation and Connectivity Modern HMCs come equipped with advanced automation features and connectivity options. Robotics and tool changers streamline production, while network connectivity allows for real-time monitoring and data analysis. 7. Maintenance and Care Best Practices for Longevity To ensure the longevity and optimal performance of HMCs, regular maintenance is essential. This includes routine inspections, lubrication, and calibration of critical components. Troubleshooting Common Issues Despite their reliability, HMCs may encounter occasional issues. Understanding how to identify and troubleshoot common problems helps minimize downtime and ensures uninterrupted production. 8. Future Trends and Innovations Improvements in Technology The manufacturing industry is constantly evolving, and HMCs continue to benefit from technological advancements. Expect to see even higher levels of automation, enhanced artificial intelligence integration, and improved energy efficiency in the future. Impact on Manufacturing Industry The increasing adoption of HMCs has already transformed the manufacturing landscape. With faster production, higher precision, and reduced lead times, businesses can stay competitive in the global market. Conclusion Horizontal Machining Centers have undoubtedly revolutionized the manufacturing sector. Their precision, versatility, and efficiency have made them indispensable in producing critical components for various industries. As technology continues to advance, we can only anticipate further innovations that will shape the future of manufacturing.

The Development of Horizontal Machining Centers The concept of machining centers originated in the mid-20th century, with significant contributions from various engineers and manufacturers. As technology advanced, so did the capabilities of these machines, leading to the development of horizontal machining centers in the late 1960s. Key Milestones in the Evolution Over the years, HMCs have undergone remarkable improvements. The integration of computer numerical control (CNC) in the 1970s revolutionized machining processes, allowing for greater automation and precision. Subsequent advancements in tooling and spindle technology further enhanced the performance of HMCs. 3. How Horizontal Machining Centers Work Basic Principles of Operation Horizontal Machining Centers use a rotating cutting tool that moves along multiple axes to remove material from the workpiece. The horizontal spindle enables efficient machining of various sides of the workpiece without the need for repositioning, resulting in faster production times. Types of Workpieces Created HMCs are incredibly versatile and can produce an array of components, including engine blocks, gears, aerospace parts, and more. Their ability to accommodate different workpiece sizes and materials makes them indispensable in modern manufacturing. 4. Popular Applications Industries Using Horizontal Machining Centers Horizontal Machining Centers find applications in diverse industries such as automotive, aerospace, oil and gas, and medical equipment manufacturing. Their ability to handle complex machining tasks with precision makes them invaluable across different sectors. Specific Use Cases Within these industries, HMCs play a pivotal role in manufacturing critical components like turbine blades, cylinder heads, and hydraulic manifolds. Their accuracy and reliability ensure that these vital parts meet stringent quality standards. 5. Comparison with Vertical Machining Centers Advantages and Disadvantages Horizontal and Vertical Machining Centers each have their strengths and weaknesses. While HMCs excel in production volume and stability, Vertical Machining Centers are better suited for intricate and smaller components. Understanding the differences helps manufacturers choose the right machine for their specific needs. Selecting the Right Option When selecting between HMCs and VMCs, factors such as production requirements, workpiece complexity, and available floor space need to be considered. Consulting with machining experts can assist in making the best decision. 6. Key Features to Consider Precision and Accuracy One of the primary reasons manufacturers opt for HMCs is their ability to consistently deliver high precision and accuracy in machining tasks. This is crucial in industries where the slightest deviation can lead to significant consequences. Spindle Speed and Power The performance of HMCs is influenced by the spindle's speed and power. Higher spindle speeds enable faster cutting, while greater power ensures the machine can handle tougher materials and heavier cuts. Automation and Connectivity Modern HMCs come equipped with advanced automation features and connectivity options. Robotics and tool changers streamline production, while network connectivity allows for real-time monitoring and data analysis. 7. Maintenance and Care Best Practices for Longevity To ensure the longevity and optimal performance of HMCs, regular maintenance is essential. This includes routine inspections, lubrication, and calibration of critical components. Troubleshooting Common Issues Despite their reliability, HMCs may encounter occasional issues. Understanding how to identify and troubleshoot common problems helps minimize downtime and ensures uninterrupted production. 8. Future Trends and Innovations Improvements in Technology The manufacturing industry is constantly evolving, and HMCs continue to benefit from technological advancements. Expect to see even higher levels of automation, enhanced artificial intelligence integration, and improved energy efficiency in the future. Impact on Manufacturing Industry The increasing adoption of HMCs has already transformed the manufacturing landscape. With faster production, higher precision, and reduced lead times, businesses can stay competitive in the global market. Conclusion Horizontal Machining Centers have undoubtedly revolutionized the manufacturing sector. Their precision, versatility, and efficiency have made them indispensable in producing critical components for various industries. As technology continues to advance, we can only anticipate further innovations that will shape the future of manufacturing. FAQs

Q: Are Horizontal Machining Centers suitable for high-volume production?

A: Yes, HMCs are well-suited for high-volume production due to their ability to handle large workpieces and their efficient chip evacuation.

Q: What industries benefit the most from using HMCs?

A: Industries such as automotive, aerospace, and heavy machinery manufacturing benefit significantly from using HMCs to produce complex components.

Q: Can HMCs work with different materials?

A: Absolutely! HMCs can work with various materials, including metals, composites, and plastics.

Q: How do HMCs compare to traditional milling machines?

A: HMCs offer higher precision, faster production times, and better chip management compared to traditional milling machines.